Rb600 Recycled Paper Pulp Cleaner for Advanced Centricleaner System in Paper Mill

Product Details:

| Place of Origin: | China |

| Certification: | ISO 9001 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Wooden Cage |

| Delivery Time: | Peak Season Lead Time: within 15 workdays, Off Season Lead Time: within 15 workdays |

| Payment Terms: | LC, T/T, PayPal |

| Supply Ability: | 40set/Month |

|

Detail Information |

|||

| Model NO.: | RB300, RB600 | Application: | Recycled Paper Pulp Cleaner |

|---|---|---|---|

| Color: | Natural Silver | Alumina Ceramic Bush: | Yes |

| Transport Package: | Wooden Case | Specification: | OEM |

| Trademark: | OEM | Origin: | China |

| HS Code: | 8439990000 | Supply Ability: | 500000000000 |

| After-sales Service: | 6 Month | Warranty: | 12 Month |

| Certification: | RoHS, ISO 9001:2000, ISO 9001:2008, CE | Surface Treatment: | Without Processing |

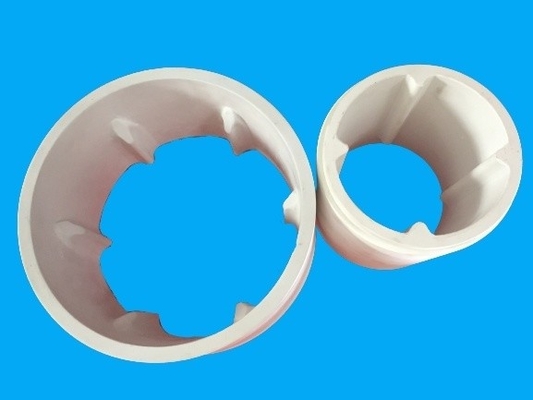

| Manufacturing Process: | Casting | Material: | PA66 & Alumina Ceramic |

| Customization: | Available | Customized Request | ||

Product Description

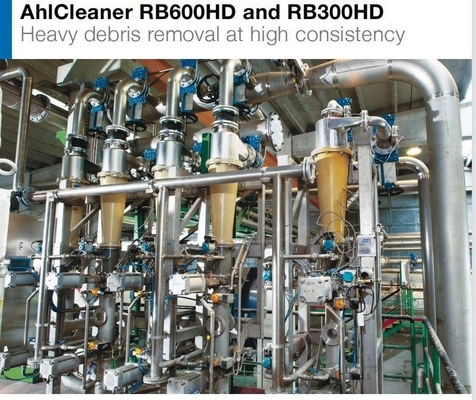

Style and size : Andritz RB300m RB600 higher Consistency Centrifugal cleaner for paper pulp Mill for factory

Material : Stainless steel 304 or 316 With alumina Ceramic Bush

RB300: USD9250/SET

RB600: USD23000/SET

Cleaners are used for recovered paper stock systems, approach flow systems, and stock preparation systems with virgin fibers.

To minimize fiber loss, the rejects have to be processed in subsequent cleaner stages. In Centrifugal cleaner systems, in most cases two or three cleaner stages are required but no more than four stages.

Based on decades of experience in paper production and stock preparation, we developed its Blue Line product line. Our customers profit from proven our quality in stock preparation and simultaneously lower costs of raw materials. Our LC and HC cleaner products are perfectly matched to each other. Take advantage of our technologies for outstanding pulp and paper quality.

Save valuable resources with our rebuild solutions and at the same time improve the performance of your existing system.

Material : Stainless steel 304 or 316 With alumina Ceramic Bush

RB300: USD9250/SET

RB600: USD23000/SET

Removal of contaminants with minimal fiber loss

Cleaning systems are used to remove coarse or fine heavy and lightweight contaminants as well as entrained air. This provides a clean fiber material but also reduces wear and tear on the downstream equipment.Cleaners are used for recovered paper stock systems, approach flow systems, and stock preparation systems with virgin fibers.

To minimize fiber loss, the rejects have to be processed in subsequent cleaner stages. In Centrifugal cleaner systems, in most cases two or three cleaner stages are required but no more than four stages.

Separate fiber and contaminants with high efficiency

Low consistency (LC) cleaners are used to remove small contaminants. The separation principle is always the same - contaminants can be separated from fibers of different densities.Based on decades of experience in paper production and stock preparation, we developed its Blue Line product line. Our customers profit from proven our quality in stock preparation and simultaneously lower costs of raw materials. Our LC and HC cleaner products are perfectly matched to each other. Take advantage of our technologies for outstanding pulp and paper quality.

Our solutions for LC cleaner rebuilds

Is your goal to increase efficiency in the cleaning process without costly but Save huge cost engineering and parts maintenance ?Save valuable resources with our rebuild solutions and at the same time improve the performance of your existing system.

Want to Know more details about this product